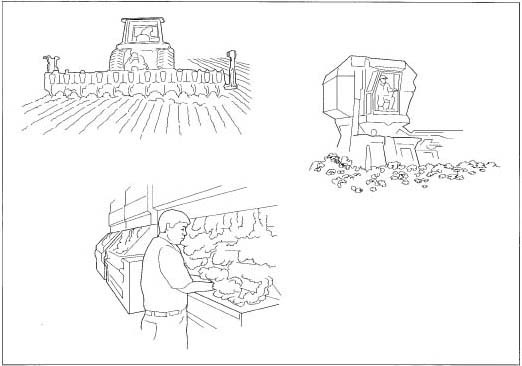

- In spring, the acreage is cleared for planting. Mechanical cultivators rip out weeds and grass that may compete with the cotton for soil nutrients, sunlight, and water, and may attract pests that harm cotton. The land is plowed under and soil is broken up and formed into rows.

- Cottonseed is mechanically planted by machines that plant up to 12 rows at a time. The planter opens a small furrow in each row, drops in seed, covers them, and then packs more dirt on top. Seed may be deposited in either small clumps (referred to as hill-dropped) or singularly (called drilled). The seed is placed 0.75 to 1.25 in (1.9 to 3.2 cm) deep, depending on the climate. The seed must be placed more shallowly in dusty, cool areas of the Cotton Belt, and more deeply in warmer areas.

- With good soil moisture and warm temperature at planting, seedlings usually emerge five to seven days after planting, with a full stand of cotton appearing after about 11 days. Occasionally disease sets in, delaying the seedlings' appearance. Also, a soil crust may prevent seedlings from surfacing. Thus, the crust must be carefully broken by machines or irrigation to permit the plants to emerge.

- Approximately six weeks after seedlings appear, "squares," or flower buds, begin to form. The buds mature for three weeks and then blossom into creamy yellow flowers, which turn pink, then red, and then fall off just three days after blossoming. After the flower falls away, a tiny ovary is left on the cotton plant. This ovary ripens and enlarges into a green pod called a cotton boll.

- The boll matures in a period that ranges from 55 to 80 days. During this time, the football-shaped boll grows and moist fibers push the newly formed seeds outward. As the boll ripens, it remains green. Fibers continue to expand under the warm sun, with each fiber growing to its full length—about 2.5 in (6.4 cm)—during three weeks. For nearly six weeks, the fibers get thicker and layers of cellulose build up the cell walls. Ten weeks after flowers first appeared, fibers split the boll apart, and cream-colored cotton pushes forth. The moist fibers dry in the sun and the fibers collapse and twist together, looking like ribbon. Each boll contains three to five "cells," each having about seven seeds embedded in the fiber.

Most steps involved in the production of cotton have been mechanized, including seeding, picking, ginning, and baling. Samples are taken from the bales to determine the quality of the cotton. - At this point the cotton plant is defoliated if it is to be machine harvested. Defoliation (removing the leaves) is often accomplished by spraying the plant with a chemical. It is important that leaves not be harvested with the fiber because they are considered "trash" and must be removed at some point. In addition, removing the leaves minimizes staining the fiber and eliminates a source of excess moisture. Some American crops are naturally defoliated by frost, but at least half of the crops must be defoliated with chemicals. Without defoliation, the cotton must be picked by hand, with laborers clearing out the leaves as they work.

- Harvesting is done by machine in the United States, with a single machine replacing 50 hand-pickers. Two mechanical systems are used to harvest cotton. The picker system uses wind and guides to pull the cotton from the plant, often leaving behind the leaves and rest of the plant. The stripper system chops the plant and uses air to separate the trash from the cotton. Most American cotton is harvested using pickers. Pickers must be used after the dew dries in the morning and must conclude when dew begins to form again at the end of the day. Moisture detectors are used to ensure that the moisture content is no higher than 12%, or the cotton may not be harvested and stored successfully. Not all cotton reaches maturity at the same time, and harvesting may occur in waves, with a second and third picking.

- Next, most American cotton is stored in "modules," which hold 13-15 bales in water-resistant containers in the fields until they are ready to be ginned.

- The cotton module is cleaned, compressed, tagged, and stored at the gin. The cotton is cleaned to separate dirt, seeds, and short lint from the cotton. At the gin, the cotton enters module feeders that fluff up the cotton before cleaning. Some gins use vacuum pipes to send fibers to cleaning equipment where trash is removed. After cleaning, cotton is sent to gin stands where revolving circular saws pull the fiber through wire ribs, thus separating seeds from the fiber. High-capacity gins can process 60, 500-lb (227-kg) bales of cotton per hour.

- Cleaned and de-seeded cotton is then I 0 compressed into bales, which permits economical storage and transportation of cotton. The compressed bales are banded and wrapped. The wrapping may be either cotton or polypropylene, which maintains the proper moisture content of the cotton and keeps bales clean during storage and transportation.

- Every bale of cotton produced in the United States must be given a gin ticket and a warehouse ticket. The gin ticket identifies the bale until it is woven. The ticket is a bar-coded tag that is torn off during inspection. A sample of each bale is sent to the United States Department of Agriculture (USDA) for evaluation, where it is assessed for color, leaf content, strength, fineness, reflectance, fiber length, and trash content. The results of the evaluation determine the bale's value. Inspection results are available to potential buyers.

- After inspection, bales are stored in a carefully controlled warehouse. The bales remain there until they are sold to a mill for further processing.

|